Feb 12, 2016· We can produce all the equipments used in CIL plant, including crusher, belt conveyor, ball mill, classifier, hydrocyclone, thickener, leaching tank, elution and electrowinning unit, .. The gold deposition rate is controlled only by mass transfer process, and its electrolytic efficiency can be indicated with the following formula:.

ball size calculation for ball mill how to make a ball mill

For wet grinding process,when charge of ball is up to 55% of net volume of the mill,the best status can be realized. The volume of ball within the mill can be estimated with formula:

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size reduction of a wide variety of materials such as minerals, ores, coal, carbon products and general chemicals.

Used Ball Mills and surplus parts for sale on EquipmentMine.

Jan 25, 2018· G1 Heat Generation Factor (RollerRaceway) . 4 Based on 90 x 106 revolutions L10 life, for The Company life calculation method. . debris that may be introduced and could reduce the ball bearing speed and lifespan. . dental equipment, elevators, rolling mills, ship rudder shafts, and aggregate crushers, among others.

is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations. Grinding circuit design tools, including for SAG millball mill circuits, and geometallurgy energy models are available to subscribers.

Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge. For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed,,

Bond Ball Mill Index Test (BRMWI) A Bond Ball Mill Index Test (BBMWI) is a standard test for determining the Ball Mill Work Index of a sample of ore. The BBMWI is a measure of the resistance of the material to crushing and grinding.

A ball mill is a type ... size reduction is done ... Aside from common ball mills there is a second type of ball mill called a planetary ball mill. Planetary ball ... How Can I calculate new ball size and . · Re: How Can I calculate new ball size and weight desing for .

Oct 17, 2018· Devon's method sounds like a good one. What I typically do is a little different. I do a sweep cut, with the cross section shape of the end mill as .

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

A ball mill is a porcelain jar a little more than half filled with porcelain balls (they can also be alumina or natural stones). Glaze is poured in, a lid secured, and it is rotated on a motorized rack (often for hours).

The mill used for this comparison is a diameter by meter long ball mill with a 5000 HP drive motor. It is designed for approximately 90 per hour.

Ball size distribution The ball load in the mill, prior to the removal of the scats, was calculated from the volumetric filling, taken from the full grindout to be 70t.

Ball End Mills Ball end mills or "ball nose end mills" are used for making full radiused grooves, generating large corner radii, or contour profile milling. General purpose ball end mills, with a 30° helix, are available in many diameter sizes and lengths.

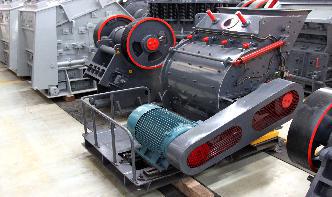

Since 1942 Strommasina Corp. has been successfully producing equipment for the mining, building, oil and gas, as well as road, metallurgical industries.

ball mill size calculation – Grinding Mill China. The optimal ball diameter in a mill. grinding quartz and copper ore in a laboratory ball mill, there has been defined a general form of the equation for determining: the optimal ball diameter depending on the grain size being ground; and the parameter of the equation through.

different top size was tested using the Bond Ball Mill Work Index methodology (Partyka, T. Yan, D., 2006). The most energy efficient media was obtained with the smallest top size (5,5 mm) when the feed size F80 was finer than 100 µm. The larger top size balls .

Size reduction and homogenization with ball mills RETSCH Product Navigator Milling Jaw Crushers ... RETSCH ball mills are suitable for a wide range of applications. Depending on the model (planetary ball mill or mixer mill), they can be used for dry, wet ... The feed size depends on the mill and can have a maximum size of 10 mm. If the sample ...

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

within the mill. In this paper, we examine the axial transport in dry ball mills. This requires simulation of the entire mill and the full volume of the charge for ... The ball size distribution used was 75 to 200 mm and the rock size distribution was 25 to 100 mm. The specific gravity of the rock was 4. The

Maximum Depth of Cut (DOC) for finishing should be less than or equal to 10% of ball diameter. Stepover should be greater than or equal to DOC. Ball nose tools are not designed for roughing.

Calculate and Select Ball Mill Ball Size for Optimum Grinding Feb 7, 2018 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do.

The grindingproduct size, P, in a Bond ball mill, which is given by the aperture size which passes 80% of the grinding product as a function of the aperture size of the test screen Pk, Can be expressed by the formula P=Pk/K2.