grinding mill used in slag cement process myzeecompus. Cement millCement mill priceRaw material millChina Powder Grinding Mill mill is widely used for the cement Iron Ore Slag Mill Processing Plants For Sale . get more info.

what is a slag mill

"Introduction to Electric Arc Furnace Steelmaking" (TC107713). The purpose of this TechCommenraw (TC107714) is to give utilities a ... integrated steel mills. Charge Materials tially charged scrap to the furnace. Although most EAF steel ... Advantages for bottom stirring y slag practice can allow volt increased (sometimes to as ...

Slag is sometimes erroneously classified as industrial waste. In fact, this product can be recycled into valuable, versatile construction materials for green use. We utilize slag, a product of steelmaking, in versatile construction material for environmentally beneficial use.

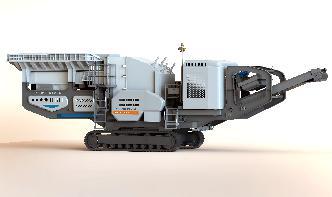

Slag Mill Slag Powder Production Line chinasand . Slag Powder Production Line is used widely in slag production industry including slag powder crusher or slag crusher for primary crushing, slag mill or slag grinder mills used for grinding slag materials, slag optional equipment for feeding and screening slag, slag mobile crusher etc.

A slag rock is an artificial rock. Slag is made as a byproduct of industrial processes such as metal mining. It is also produced by iron smelting such as in steel mills.

Slag mill is the key equipment used for regrinding the slag after it is precrushed. It is mainly applied in the superfine slag powder production industry and . Get Price And Support Online; ball milling equipment for steel slag. steel mill slag prices. steel slag, ball mill machine most commonly used mining,thermal power,sand processing production of industrial milling equipment .

The year was 1960 and the location was a slag heap in West Mifflin, Pennsylvania known as Brown's Dump. Slag is a byproduct of steelmaking. When rock containing iron ore is melted in a furnace, the impurities separate from the iron and become a molten rock called slag.

Effective mineral slag grinding mill,slag grinding mill for gold copper Hot sale slag grinding mill for sale with large capacity and low price. Get Price And Support Online. Efficiency and grinding media filling level IEEE Conference . Over the last 50 years, the specific energy required to reduce a given mineral or This presentation was given ...

For a mill that grinds slag to 5500 Blaine, the maximum practical level of feed moisture is only on the order of 24%, H2O if the mill is not equipped with a drying chamber. If the slag is fed with hot clinker to the mill, then it may be possible to have a substitution rate of 515% slag, depending on the moisture level, before drying becomes a limitation.

Grinding of blast furnace slag is conventionally performed in a tube mill with a dryer, which is a powerintensive option. Energy efficiency of this process can be improved by grinding the blast furnca slag using vertical roller mills (VRM) or by using a VRM as a pregrinding step for the tube mills.

What is Slag? | Australian Steel Mill Services. What is Slag? There are two distinct types of slag produced at the BlueScope Steel Port Kembla Site; Blast .

As a result of its many years of activity in electric arc furnaces and oxygen steel plant, FUSIREF has developed activities covering slag management, transport, processing and recycling.

CHAENG slag vertical roller mill is applied to the construction of GGBFS production line, such as Indonesia with 300,000 tons/year nickel slag powder production line. By now, CHAENG has built more than 90 slag vertical rollers mill production line at home and abroad.

Slag Car This huge ladle is one of two mounted on a slag car. Slag is a layer of impurities that floats to the top of the molten iron; it was skimmed off to be poured into .

Slag's ain't Slag's SLAG is a broad term covering all non metallic co products resulting from the separation of a metal from its ore, Its chemistry and morphology depends on the metal being produced and the solidification process used.

91 IRON AND STEEL SLAG Events, Trends, and Issues: Aircooled blast furnace slag is in declining domestic supply owing to depletion of old slag piles and the closure of many blast furnaces over the years for economic and/or environmental reasons.

The process begins with a Slag Analysis of a customer's current slag, proceeding to on site observations of practices and procedures, then during trials we take samples and evaluate the current slag practice, finally making recommendations to products and practices.

One of the most important tools for slag control is the fast, reliable slag analyzer, which allow quick and reproducible analysis of all the oxides in the slag. Factors for slag analysis

Blast furnace slag is a nonmetallic coproduct produced in the process. It consists primarily of silicates, aluminosilicates, and calciumaluminasilicates. The molten slag, which absorbs much of the sulfur from the charge, comprises about 20 percent by mass of iron production.

Steel mill workers were exposed to different types of asbestos products such as: Machinery and Equipment Insulation : Asbestos was used to insulate equipment including, ovens, hot blast stoves, furnaces, rolling mills, tanks, boilers, cranes, molding boards and steam pipes.