Following is the procedure of manufacturing cement by dry process using modern technology: Boulders of limestone upto size are transported in huge dumpers upto 300kN capacity and dumped into the hopper of the crusher.

dry process cement manufacturing

The cement manufacturing industry is identified by North American Industry Classification System (NAICS) code 32731 (formerly identified as SIC code 3241). The cement industry "comprises establishments primarily engaged in manufacturing portland, natural, masonry, pozzalanic, and other hydraulic cements.

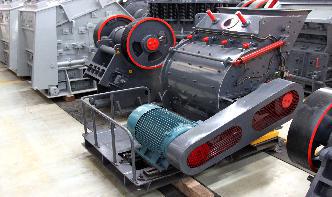

dry and wet process of cement manufacturing. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. Read More

Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc..

At present, about 78% of Europe's cement production is from dry process kilns, a further 16% of production is accounted for by semidry and semiwet process kilns, with the remainder of European production, about 6%, coming from wet process kilns.

Cement the common binding material which has been used for several days on wards. There are many types of cements but portland cement is used commonly. The manufacture of Portland cement can be done by two methods Process Process In this ...

dry and wet process of cement manufacturing. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. Dry Process for Manufacturing of Cement In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill.

Dec 24, 2016· cement manufacturing process December 24, 2016 shanmukha Leave a comment The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement and a high rate of production.

dry process cement manufacturing – Grinding Mill China. How Cement Is Made – Portland Cement Association. The most common way to manufacture portland cement is through a dry method. The first step is to quarry the principal raw materials, mainly limestone, clay, and.

Cement Manufacturing Dry Process Online Civil. The entire manufacturing process in a modern plant is now controlled through a microprocessor based .

Process of Sprayed Concrete MixMethods, Equipments And . Sprayed concrete mix process consists of dry mix and Once the production is complete, the mix is taken to materials or mixes of dry sand and cement.

The dry process is preferred in places where hard and crystalline raw materials are available. This process has the advantage over the wet process, the fuel consumption is low. The raw material is first crushed in the dry state in multi chamber tube mill.

dry process cement manufacturing . New dryProcess cement production technology -China Buliding. Feb 2, 2009 The new dryprocess cement production technology, developed by Tianjin Cement Industry Design and Research Institute (TCDRI), was » Learn More. Energy and Cost Analysis of Cement Production Using the Wet and.

When MC < 8%, the dry process is used. The feedstock is interground and blended in a dry form. For MC between 8 and 15 %, a raw meal slurry (similar to wet process) is prepared, sent through a short kiln with a cyclonic preheater.

Technoeconomic and environmental analysis of a dry cement process was conducted. Energy utilization of the plant was GJ at per tonne of cement. Pyroprocessing unit is the major energy consumer.

The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement and a high rate of production.

Dry process These are two different processes of manufacturing cement. wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are.

Preparing Portland cement 1 The limestone, silica, and alumina that make up Portland cement are dry ground into a very fine powder, mixed together in predetermined proportions, preheated, and calcined (heated to a high temperature that will burn off impurities without fusing the ingredients).