In modern industry, limestone is the main raw material for making cement, lime and calcium carbide. It is an indispensable flux limestone in metallurgical industry.

raw grinding ball mill feed size and capacity

Rawmill systems typically require a feed of maximum size 510 cm, so a crushing stage is first required. ... The design reverted to the idea of the peripheral discharge ball mill, and the first, coarsegrinding chamber discharged through sieves into a surrounding collection space. ... The first raw ballmills to be designed specifically to be ...

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

The grinding jar for the Bond Index Rod Mill is 12″ x 24″ in size and has a waveshaped design. At least 15 to 20 kg sample material is required to simulate a closed grinding circuit in a ball or rod mill.

raw grinding ball mill feed size and capacity – Grinding ... Tube ball millHenan Bailing Machinery,Tube ball mill is a horizontal rotating device transmitted by the outer gear, with two grinding chamber,it's a kind of grid ...

Effect of High Pressure Grinding Rolls HPGR pregrinding and ball mill intermediate diaphragm grate design on grinding capacity of an industrial scale High Throughput Cutting Mill The hard, tool steel cutting edges on the knives allow milling of a wider range High Capacity Cutting Mill with Auto Feed Hopper which allows you to load the

Dry and wet grinding common. Ball mill photographed by Ron Frisard and shared on Flickr, CC ... wet and dry grinding, over size feed and under size grinding. ... is a function of mill capacity and diameter,,P M = Mill Constant * (Mill Diameter ) n where n = to

high capacity grinding wet ball mills Autogenous mills, semiautogenous mills and ball mills for wet grinding lines to meet the high standards demanded by our clients in the minerals . 950 1350 small diameter ball mills.

COMPARISON OF GRINDING MILLS TYPE OF MILL MEDIA SIZE RPM TIP SPEED (fpm) ... or feed rate of raw material. In addition to reducing particle size, Attritors also can create the ... or for fine grinding in general. Ball mills can blend and grind at the same time, yielding a fine, intimate mixture. ...

HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process is simple, small footprint, low noise, small dust, easy maintenance, low operation cost, low consumption and other advantages of .

POLYCOM® for raw material grinding was introduced in the Indian market during mid nineties, basically for capacity enhancement of existing ball mills. Over the last 25 years, there has been

DOVE ® offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material processing. Wide range of capacities DOVE ® offers variety of models with a wide range of capacities, applicable for laboratories (200 gr. up to 2000 kg.) and small up to big scales productions.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill » Learn More ball mill calculation

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and .

Cement mill notebook SlideShare. CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 [email protected]... feed size, fineness of the finished product, open or closed circuit grinding, and grinding capacity of the mill depends on the cross section and hence the diameter of the mill.

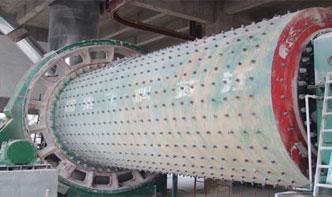

Ball mill Wikipedia. A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum,building material, glass, .

capacity of grinding media in ball mill . calculating of volume in ball mill capacity. an m diameter sag mill with lid grinding a copper ore,and predicted maximum capacity and minimum kwh ton at about ball load at total filling two fag mills of volume flow rate and n is an empirical m constant in terms of the by impact from media were calculated from the equations developed nbsp...