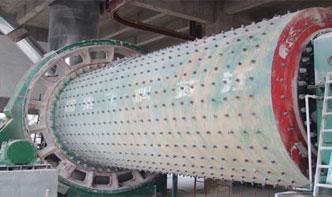

Ball mill is a kind of grinding equipment, which is widely used in ore dressing process. Dry ball mill and wet lattice ball mill can be selected according to material and ore discharging mode. Ball mill is composed of horizontal cylinder, hollow shaft and grinding head.

find total ball weight and size ball mill

The mill speed is expressed in a percentage of the critical speed. ... weight of ball charge, shape of liners, size of grinding .... 6) speed n is then calculated as: (Z) ... » Learn More. ... and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical ... Calculating how fast a Jar needs to spin is a little tricky, but simple ...

n = Speed of ball mill in rpm. Example 1: Let the internal dia of the mill be mtr and internal length be mtr. If Alumina grinding media is used density d =

Therefore, prerequisite of verify the total weight is to add the steel ball and material in the mill and the weight is less than allowable value close to the ball mill and motor power. 2, Determine the maximum steel ball diameter .

Dec 23, 2013· Particle size, number of balls, particle density, hardness, number of media used, time of grinding, and speed of the ball mill (rpm) are factors which will affect the process of milling. Size: The smaller the media particles, the smaller the particle size of the final product.

Polished stainless steel vacuum grinding jars for planetary ball mills. Each jar set includes grinding jar, lid, silicon vacuum sealing gasket and a mixed sizes of stainless steel grinding balls .

PARTICLE SIZE REDUCTION IN THE BALL MILL 83 size. Although no experimental data was presented, Garlick ... The variables investigated were; the weight of the balls in the mill, the nature of the grinding media and the weight of material added to the mill. ... Total Milling Time (min.) Required to Mill 50% of Sample Down to 15Oum. ~ ~~

Ball Weight and Density How much will a ball of a given diameter in a certain material weigh? The answer is calculated by multiplying the volume of the ball by the density of the material. text"Weight" = text"Volume" ⋅ text"Density" For example, calculate the weight of a two inch diameter lead ball:

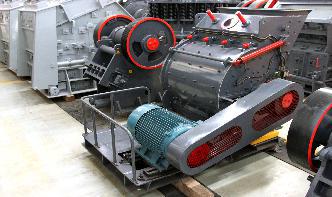

The ball mill is mainly composed of a feeding mouth, a discharging mouth, the rotary part and the transmission part (reducer, small transmission gears, engine and electric control). The hollow shaft is made of cast steel, the interior lining board changeable.

ball mills operating in just America alone. ... enter the media size and a rotation speed to determine the jar size for that combination. Calculations are ... as well as to lighten the weight of the The material charge is equally important in running an efficient milling

Under normal operating conditions, the mill ball loading is 30% of total mill volume, mill rotational speed is 75% of critical speed, slurry solids concentration is 75%, solids feed rate is 330 tph.

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products.

Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry.

» Average Production of MIDES® Ball Mill Sorter = 70 to 110ton 1 ... » Time spent to Load the Mill = 8hours » Total time of stopage of the Mill = 48hours ... • Weighing is made by different balls size. Electrical Power of the MIDES® Sorter:

JKTech Laboratory Services Bond Ball Mill Index Test (BRMWI) A Bond Ball Mill Index Test (BBMWI) is a standard test for determining the Ball Mill Work Index of a sample of ore. ... to determine the size of mill required based on throughput, and therefore motor power.

DOVE ® offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material processing. Wide range of capacities DOVE ® offers variety of models with a wide range of capacities, applicable for laboratories (200 gr. .

Ball size determines the degree of product fineness. The FL ball mill can operate in an open or closed circuit and has a corrugated lining in the grinding compartment for added effectiveness. The ball mill consists of standard modules that can be configured for .

media or volume, Minc = weight of the charge, ... dates obtained by exploitation of the balls mills [1,2]. The balls size distribution must allow replenished ... The total wear of grinding media, during the cement clinker (balls of forging steel and hardened with 600 Brinell, and cylpebs by ...

Grinding in ball mills is an important technological process applied to reduce the ... Besides particle size reduction, ball mills are also widely used for mixing, ... distributed in the smaller sizes. It should be noted however, that the total mass remains constant. Fig. 3

EURASIAN MINING • 1. 2015 Technology and technics of ore preparation processes 7 feed for the rod mill, 10000 μm in accordance with Table. The value of P 80 is accepted based on the required grainsize characteristics of the ball mill discharge.

With the coarser mill feed, the 105 mm ball size was unsuitable and the mill throughput dropped from 350 tph down to 275 tph. With the return to SABC circuit mode, .

Media Charge_Optimal Ball Size Ball Mill. Ball Mill Audit_Level B. SAG Ball Mill Dimensioning. Tromp Curve Calculation. ... Considering the weight of mill lining and grinding media, work out the motor power required, in consultation with the mill manufacturer. ... Ball Mill Calculations. Uploaded by. vvijaybhan. calculation of cement mill ...

• Weight of the balls: With a heavy discharge of balls,we get a fine can increase the weight of the charge by increasing the number of balls or by using a ball material of high density • Speed rotation of Ball mill: low speeds,the balls simply roll over one another and little grinding is obtained while at very high speeds the ...

mineral processing operation and can be 80% of total electrical energy consumed at a specific ... ball or rod mills for further size reduction. Types of Mill ... The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight measurement or .