electric arc furnaces, and plants producing iron by direct reduction. Other processes associated with steelmaking, such as ladle metallurgy, argonoxygen decarburization, and casting are also

manufacturing of iron by electric arc furnace in ppt

C open hearth furnaces, no longer used for domestic steel production; C basic oxygen furnaces, with 62 percent of the t otal; and C electric arc furnaces, accounting for the remaining 38 percent. The latter predominantly uses scrap (, nonmineral material) as feedstock and .

Using Oxygen Reaction as Electricity Saving in Electric Arc Furnace Steel Making ... iron, carbide etc. helps to increase productivity 3. Various purity of oxygen is used in the steelmaking industry. For example % oxygen is used mostly in the open heart furnace and EAF. Oxygen of 95% purity is .

Steelmaking by Induction Furnace. Posted by Satyendra on Mar 26, 2013 in Technical ... Because of use of sponge iron the trace elements in the steel made in the IF remains under control. ... The comparison of the operating parameters of induction furnace with those of electric arc furnace .

Conveyor buckets take iron ore, limestone and coke to the top of furnace 4. Once inside the furnace the whole mixture is 'fired', this brings it to a white hot temperature. 5. Smelted iron runs to the bottom of the furnace and is tapped off 6.

CONTIARC® furnaces for cast iron production 12 13 Technology components, Process control and visualisation ... SMS Demag Electric Arc Furnaces TECHNOLOGY COMPONENTS 12 Power conducting arms (PCA). Top lance equipment. Acoustic slag .

the use of electric arc furnaces (EAFs) for the production of steel has grown dramatically in the United States. In 1975 ... "Introduction to Electric Arc Furnace Steelmaking" (TC107713). The purpose of this TechCommenraw ... iron, and silicon and the burning of natural gas with oxyfuel burners. About

Electricarc steelmaking About onequarter of the world's steel is produced by the electricarc method, which uses highcurrent electric arcs to melt steel scrap and convert it into liquid steel of a specified chemical composition and temperature.

blast furnace, electric arc furnace, and hot strip mill, have evolved continuously over the decades and are likely to remain a part of steelmaking in the future. Currently, the two major steelmaking routes use either the basic oxygen furnace (BOF) or the electric arc furnace (EAF) or some combination of the two.

Understanding Electric Arc Furnace Operations For Steel Production Introduction The use of electric arc furnaces (EAF) for steelmaking has grown dramati ... elements such as carbon, iron, and silicon and the burning of natural gas with oxyfuel burners. About 53% of the total energy leaves the furnace .

Modern electric arc furnaces can make up to 150 tonnes of steel in a single melt. The electric arc furnace consists of a circular bath with a movable roof, through which three graphite electrodes can be raised or lowered.

Globally, steel is produced via two main routes: the blast furnacebasic oxygen furnace (BFBOF) route and electric arc furnace (EAF) route, which are shown in Figure 2. Variations and combinations of production routes also exist. The BFBOF route produces steel predominantly using raw materials such as iron ore, coal, limestone and recycled steel.

The increasing role of direct reduced iron in global steelmaking or which is produced as a byproduct in the manufacture of steelcontaining parts or goods (prompt

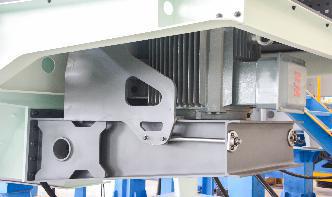

The electric arc furnace as the name suggests is a furnace in which heat is generated with the aid of electric arc produced by graphite electrodes. The main components of the electric arc furnace are the furnace shell with tapping device and work opening, the removable roof with the electrodes and a tilting device. The furnace shell is circular and with a refractory lining.

Production and applications of electricarcfurnace slag as solid waste in environmental technologies: a review. Soraya Hosseini Department of Chemical Engineering, ... blast furnace (BF) iron slag, basic oxygen furnace (BOF) and electricarcfurnace (EAF) slag. EAF slag is the byproduct of the steel production process in an EAF.

An electric are furnace is recognized as a principle furnace that is used for production of steel. Knowing the primary application of electric arc furnace, it can be said that it is used for remelting the steel scrap. There are two types of arc furnaces. Direct furnace has three electrodes that .

Home > Tips and Facts > Foundry Melting Furnaces > Cupola Furnace. The Cupola Furnace. For many years, the cupola was the primary method of melting used in iron foundries. The cupola furnace has several unique characteristics which are responsible for its widespread use as a melting unit for cast iron.

Alternatively, "minimills" produce steel from metal scrap using Electric Arc Furnace (EAF) technology, without operations for coking or ironmaking. Coke, which is the fuel and carbon source at integrated mills, is produced by heating coal in the absence of oxygen at high temperatures in coke ovens.

and one third is produced in 246 electric arc furnaces (EIPCCB 2001a). In 2005, there were 3 integrated iron steel works operating in the UK, all owned by Corus.

ElectricArc Furnace (EAF) A Revolution For Steel Manufacturers Posted October 29, 2018 by srikanthgtbrc The global iron and steel mills and ferroalloy manufacturing market was valued at around 2266 billion in 2017.

VŠB Technical University of Ostrava Faculty of Metallurgy and Materials Engineering Iron and Steelmaking (Study Support) Prof. Ing. Jiří Bažan, CSc.

making furnaces from cokefed blast furnaces to electric arc furnaces were built and new types of refractory were developed for different applications (see Table 1).

Available online at ** ScienceDirect JOURNAL OF IRON AND STEEL RESEARCH, INTERNATIONAL. 2007, 14(5): 0106, 55 Mass Balance Modeling for Electric Arc Furnace and Ladle Furnace System in Steelmaking Facility in Turkey Ismail Ekmekci1, Yasar Yetisken1, Unal Camdali2 (1.

Electric Furnace Steel Production the production of steel in electric furnaces at metallurgical and machinebuilding plants. Steel intended for further conversion is melted primarily in arc furnaces having a basic refractory lining.

to that of a small blast furnace. 1. Characteristics of reduced iron The MIDREX process produces direct reduced iron (hereinafter referred to as DRI ). The process reduces iron ore using a reforming gas made from natural gas. The DRI is used mainly as the raw material for electric arc furnaces (EAFs), as a clean iron source substitute for scrap iron.