Fives installs raw meal grinding plant at QNCC World Cement An FCB B mill for raw meal grinding has been successfully installed at Qatar National Cement Co's new . Get More Info; Loesche to deliver three VRMs to Sohag plant.

cement raw meal grinding

Raw meal preparation; Grinding; Feeding and conveying; Air pollution controlling; Clinker production; Preheating; ... Home > Products > Cement production line > Raw meal preparation > Grinding > Vertical mill Vertical mill for raw materials Slag vertical mill

The raw material is dried ... steps within the crushing and grinding process is kWh/ton of raw meal. blending and homogenization in cement . procedure for relocating a vertical raw mill in cement ...

The size distribution of the grinding media in the coarse grinding compartment is designed for the coarsest particles in the mill feed material and to ensure adequate fineness of .

Portland cement is the most common type of cement in the world. It is used primarily to make concrete, mortar, and grout. Portland cement manufacturing begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is .

raw meal homogenizing factor Grinding Mill China. KeyWords Dynamics, Raw meal, Quality, Mill, Grinding, Model, Uncertainty. 1 Introduction. One of the main factors primarily affecting the cement .

The size distribution of the grinding media in the coarse grinding compartment is designed for the coarsest particles in the mill feed material and to ensure adequate fineness of .

The consequences of poorly prepared raw meal are well known. High lime causes meal to be ... That is why ABB has developed OptimizeIT Raw Mix Preparation (RMP): to offer raw mix quality assurance to the leaders of the cement industry. ..., from the quarry to its grinding, making sure that your quality targets are reached at the lowest ...

For grinding raw meal, cement, slag and coal. Cement Raw Material Loesche. The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well as a coal mill with an output of 45 t/h. VIEW MORE.

Like the vertical roller mill, the Horomill ... bucket elevator mill and is used for producing raw meal and, in particular ... meantime 54 Horomills have been sold, for cement grinding ..... the basics were adapted from proven technologies.

Raw Meal Preparation Grinding the raw material with both horizontal and vertical mills requires vast amounts of energy. As a result, the main challenge in the grinding process is to minimize energy consumption across the board.

Highpressure grinding – an efficient way to produce cement raw meal. B. Benski, S. Diedenhofen, thyssenkrupp Industrial Solutions AG, Beckum, Germany . The cement industry is moving towards greener technologies by reducing power and heat consumption. The characteristics of cement raw materials have a major effect on the energy consumption of ...

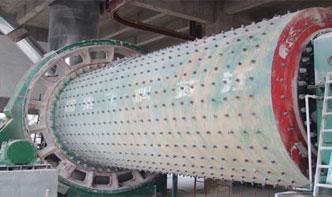

For the cement industry the ball mill was really an epochmaking breakthrough as for almost. 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Cement Raw Materials. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The xcoordinate indicates which .

Modeling of Raw Materials Blending in Raw Meal Grinding Systems TSAMATSOULIS DIMITRIS Halyps Building Materials SA, Italcementi Group, results indicate high parameters uncertainty due to the large number of disturbances during the raw mill operation, cement quality is .

Home Our Solutions Cement Raw meal grinding aid. Raw meal grinding aid. CHRYSO®AMC 12. CHRYSO®AMC 12 is specically formulated to improve the grinding of raw meal Product details . CHRYSO® AMA 30 L. READY TO USE ACTIVATOR WITH GRINDING AID PROPERTIES 28 days strengths enhancer Product details ...

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products.

Raw Material Grinding. Next, a measured quantity of limestone is extracted from our limestone hopper. Additives, such as laterite, iron ore or clay, are also extracted from their respective hoppers and mixed with the crushed limestone.

Effective Optimization of the Control System for the Cement Raw Meal Mixing Process: Simulating the Effect of the Process Parameters on the Product Homogeneity . DIMITRIS TSAMATSOULIS . Halyps Building Materials, Italcementi Group ... modules in the outlet of an actual raw meal grinding

Apr 04, 2011· Re: Raw meal to clinker ratio. Hello Arvind, The calculations assume that are measuring the feed rate of kiln feed which already contains the recirculation dust. ie in the situation where you are adding the recirculating dust to the fresh raw meal in the kiln feed bin, with the kiln feed weigher located after the kiln feed bin.. If you are measuring the kiln feed rate before the addition of ...

Very fine grinding produces a fine powder, known as raw meal, which is preheated and then sent to the kiln. The material is heated to 1,500°C before being suddenly and dramatically cooled by bursts of air.

Jun 21, 2011 grinding the quantity of cement raw material in a roller grinding mill in the presence of the supply of hot gas to produce a raw powdergas . ... They are used in grinding of cement raw materials (raw meal) ( limestone, clay, Check price. Ball Mill > Grinding drying > Raw Material Preparation > Cement .

Extraction of the raw material (limestone, shale, silica, and pyrite) is done by blasting or by scraping with the use of shearer loaders. The material is delivered to the crusher where it is reduced to chunks by crushing or pounding.