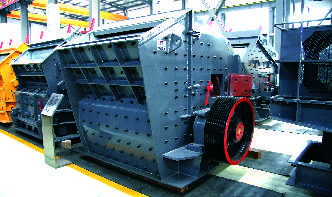

The production of activated carbon has environmental impacts that can be mitigated by the careful management of process, selection of sustainable raw materials and the reuse of byproducts. Each Jacobi facility operates modern, efficient processing equipment.

activated carbon processing

Activated carbon adsorbs organic material because the attractive forces between the carbon surface (nonpolar) and the contaminant (nonpolar) are stronger than the forces keeping the contaminant dissolved in water (polar).

At our facilities, adsorbed organics are destroyed during the thermal process and the activated carbon's adsorptive capacity is restored up to 95% of the original levels. New carbon is added to make up for any minor loss during at the process and the rejuvenated carbon .

Global Activated Carbon Market Overview : Global Activated Carbon Market is expected to reach billion and by 2024 growing at a CAGR of % from 2016 to 2024. Activated carbon is a type of carbon processed to have small and fewer amount of volume pores that increase the surface area offered for adsorption or else chemical reactions.

The procedure for processing activated carbon typically consists of a carbonization followed by an activation of carbonaceous material from vegetable origin. Carbonization is a heat treatment at 400800°C which converts raw materials to carbon

In the adsorption process, molecules of a contaminated gas are attracted to and accumulate on the surface of the activated carbon. Carbon is a common

To see more about a treatment process simply select the treatement process from the list provided.

Process overview. Activated Carbon is used in many industries as an absorber from waste water, to slurries and gases. The absorptive properties of activated carbon are due to the microporous structure of each grain resulting into large surface area per unit column of carbon.

quality. This paper discusses the production of activated carbon from an Illinois coal with a two and a threestep process. EXPERIMENTAL The primary objective of this study was to demonstrate that an activated carbon with acceptable commercial properties could be made from a 20x100 mesh fraction of an Illinois Basin coal (IBC 106).

Gas Processing Refiners of natural gas and manufacturers and users of other highpurity gases depend on activated carbons to remove contaminants and to capture mercury compounds that can harm process equipment.

Dec 05, 2014· This animation takes you through the process of manufacturing activated carbon.

Carbon columns consist of large columns (5 to 8 ft diameter) and 15 to 20 feet in height, charged with activated carbon. The minimum load of carbon rule of thumb is one pound of activated carbon per ounce of gold present in the solution.

ACTIVATED CARBON COLUMNS PLANT DESIGN 110 CHAPTER 3. ACTIVATED CARBON COLUMNS PLANT DESIGN Maybe, the first question that we have to ask ourselves is related to the decision of an adsoprtion process using activated carbon for the removal of micropollutants is efficient. The theory says that the adsorbability of an organic

Norit GAC 1240W, from coal, for potable water processing, steam activated, granular ... Activated Charcoal, Activated and Mesoporous Carbon, Adsorbents, Filter .

How to Make Activated Charcoal at Home We are often asked, "Please explain to me how to make activated charcoal at home." To make activated carbon, you first need to understand that there are two basic methods of activation steam activation and chemical activation.

A process is described for the manufacture of activated carbon in the form of a powder, as granules or as extrudates. The process includes treating a biomass feedstock, such as woods, coconut shells, fruit pits, peats, lignites and all ranks of coal with a processing agent and an activation agent.

Activated Carbon – Custom Processing The processing plants of Asbury Carbons specialize in the CRUSHING, SCREENING, GRINDING, PELLETIZING and PACKAGING of all carbon products. Also available, BLENDING and DRYING of your carbons. Packaging .

Activated carbon that is used to purify water upstream of a carboninpulp (CIP) process—by capturing organic compounds that are likely to foul the carbon in the CIP reactors— needs periodic thermal treatment to selectively remove the organic adsorbates and thus restore its activity.

Activated carbon works via a process called . adsorption, whereby pollutant molecules in the fluid to be treated are trapped inside the pore structure of the carbon substrate. Carbon filtering is commonly used for water purification, in air purifiers and industrial gas processing, for example the removal of siloxanes and hydrogen sulfide from biogas.

In the process of washing activated carbon, a dilute hydrochloric acid solution (3%) is circulated/pumped into the elution acid dissolves inorganic foulants such as calcium carbonate, magnesium and sodium salts, fine ore Minerals such as silica, and fine iron particles.

Oxbow Activated Carbon is a leading manufacturer of Process Water. Process water is a broad term that covers many applications such as product water for bottlers, brewers and fruit juice, boiler water, wash water, and any other water used in processing or as part of the end product.

Combined CausticThermal Regeneration— In the combined causticthermal process, the chromiumladen carbon was first regenerated by caustic desorption (1% NaOH), and then the carbon par ticles were driei mentioned above. tides were dried at 103°C and thermal activated at 950°C in C02 gas as Desorption Capacity— Carbon was exhausted in a ...

Calgon Carbon is the world's largest producer of granular activated carbon. Flue Gas Mercury emissions from coalfired power generation, cement manufacture, waste incinerators, and industrial boiler applications are a critical environmental concern.