in concrete, the chemical reaction between cement and water. the features of this reaction are a change in matter, in energy level, and in rate of reaction intake hopper the part of the pump that receives and holds concrete before it is sucked into the pumping cylinder

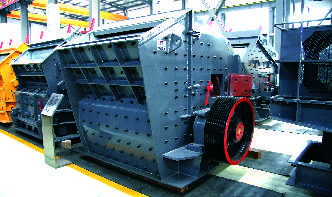

pouring method for the cement mill hopper

Burning in a kiln – formation of cement clinker. The next step in the process is to heat the blended mixture of raw ingredients (the raw mix) to convert it into a granular material called cement .

: Pouring concrete into deep forms in layers, A) Proper way of pouring concrete, B) incorrect method of pouring When height of forms in not large and concrete poured from the top of the forms, then the ACI code recommends discharging concrete into light hopper and then place concrete into its final location as explained in Figure 3.

The method of the wheel mill (original of Neolithic period) uses a flat stone slab and also a grinding stone. The wheel, operated by hand, is used to grind grains that are deposited on the slab. Two to three passes of the wheel is enough to get a coarse meal that falls gradually from the slab.

Pouring Method For The Cement Mill Hopper sayora. According to the research team atBall Mills Ball Mills Cell Disruption Method Method Statement For Floor Grinding. method of calculating supporting structure for vibrating .

The invention relates to a method for producing a cement clinker using flaming slag. The inventive method consists in pouring a slag in a smelting chamber, in injecting lime into a melt and in melting a clinker mixture to the fluid state thereof by burning a fuel mixture.

optimum clinker temperature for cement mill Chromate reduction in cement using ferrous sulfates 2 Depending on the origin of the raw materials used and the clinker production conditions, cement contains up to 30 ppm hexavalent chromium (chromate).

The shaft was concreted through a hopper having a branch pipe 3035 cm in diameter and m in length, with layer compaction of the concrete mix, which was of .

watercement ratio The ratio of the amount of water to the amount of cement in a concrete mixture. The key to producing highquality decorative concrete is to keep the watercement ratio as low as possible without sacing workability.

additives and cement 14 Hopper discharge and crusher feeding 16 Proportional feeding, proportional discharge 17 Silo and hopper discharge ... Mill hopper feeding. WE CONVEY QUALITY 10 Conveying oF rAW meAL, Cement And AdditiveS BuCKet eLevAtor With SteeLreinForCed BeLt tyPe BWg

a cement mill is the equipment used to grind the cemtec grinding mills, 300 tpd gold plant,, cone crushers, china ball mill, ball mill manufacturers, Get Price. cement vertical mill wear rate in .

pouring method for the cement mill hopper India Quarry equipment: pouring method for the cement mill hopper 12/10/2012 · pos no 06 01 01 12 for ok cement mill cylinder piping. posho mill for sale in uk. postView more.

Toggle bags method; Bagged concrete method; 1. Tremie Method of Underwater Concreting. Underwater concreting using tremie method is convenient for pouring large amount of high flowable concrete. The concrete is moved to the hopper by either pumping, belt conveyer or skips.

The dry materials exiting the mill are called "kiln feed". Size of the kiln needed for manufacturing of cement is smaller. Difficult to control mixing of Raw materials, so it is difficult to obtain a better homogeneous material. Fuel consumption is low, 100 kg of coal per tonne of cement produced. Cost of production is less.

The clinkers are grinded finely into powder in ball mill or tube mill. Powdered gypsum is added around 23% as retarding agent during final grinding. The grinded cement is stored in silos, from which it is marketed either in container load or 50kg bags.

Batching Of Concrete Method Statement The scope of this procedure covers checks required to be carried out prior to and during the site batching of concrete. ... .3 Cement (in bulk): i) The silos shall be weatherproof and the mechanism will be cleaned regularly in accordance with manufacturer's manual. ... Check the zero reading when hopper ...

Building Materials 10 Testing Methods page 68 pour the water into the bowl and add the cement start the mixer immediately at low speed (see Tab.:29) and, after 30 s add the sand steadily during

pouring method for the cement mill hopper. raw mill hopper cement plant – Grinding Mill China. pouring method for the cement mill hopper[crusher and mill] type stacker reclaimed and transferred to raw mill hopper Hopper plant for Lafarge's cement works in pouring method for the cement mill hopper .

The cement mill Understanding Cement Brief description of a cement mill. ... reading an article or two is perhaps not the best way to get a clear picture of a complex process like cement production.

The Mini Hopper attaches to the end of a ready mix chute to distribute concrete easily and accurately. Attaches to the end of a ready mix chute to distribute concrete easily and accurately. Supplied with a 6 ft. long 8" diameter elephant trunk.

pouring method for the cement mill hopper[crusher and mill] N Cement load out O Raw mill feed belt P Raw mill weigh hopper, Concrete Design Ideas,, ...

The purpose of this review is to evaluate the adequacy of the (STA) Department of Transportation's (STA's) procedures for bridge deck construction. This review will focus on the entire bridge deck construction process from portland cement concrete mix design through curing and texturing.

Oct 13, 2012· On this end, I've been opening and pouring the bags in the garage into a clean 5gallon bucket. From there, it's a short 30 pace walk into the home where I'll SLOWLY scoop the pellets from the bucket into the hopper using a 4quart grain scoop.