The calcination of calcium carbonate (limestone) is an important step in the regeneration of kraft pulping chemicals and in the production of industrial calcium oxide (quicklime). Better understanding of the kinetics can lead to improved lime kiln efficiencies in both production rate and specific energy use.

furnace for limestone

Start studying Unit 13 Chapter 58 Fluidized Bed Combustion. Learn vocabulary, terms, and more with flashcards, games, and other study tools.

A process and apparatus for burning limestone to produce calcined lime in which limestone is burned continuously in a vertical kiln provided with a plurality of fuel injectors which permit pulsed introduction of fuel so as to ensure a lamellar flow of fuel through the kiln and a controlled release of heat.

Limestone, coke and sinter Raw materials for steelmaking Level .... Limestone, coke and sinter ... additives are also necessary for the production of raw ... heat and serves as a reducing agent and supporting matrix in the blast furnace.

Large scale iron ore smelting has been carried out in numerous types of blast furnaces since the industrial revolution, with the basic ingredients of coke, iron ore and limestone remaining unchanged, being loaded into the blast furnace from where the molten iron is tapped into molds.

Limestone is added to meet the requirements of steel customers in the blast furnace process. The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed

limestone used in blast furnacecrusherasia limestone used in blast furnace This page is provide professional limestone used in blast furnace information for you, we . More Info Blast furnaceWikipediaA blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally iron, but also others such as lead .

Limestone Furnace Slate Hearth Slab Stone For Stove, US 50 80 / Set, Fujian, China (Mainland), XPIC, from Xiamen Phoenix Industrial Co., Ltd. on

During the ironmaking process, a blast furnace is fed with the iron ore, coke and small quantities of fluxes (minerals, such as limestone, which are used to collect impurities). Air which is heated to about 1200°C is blown into the furnace through nozzles in the lower section.

Jan 05, 1993· A process and apparatus for simultaneously removing NO X and SO X from the exhaust of a furnace includes an injection of limestone into a region of the furnace having a temperature of about 2,000°2,400° F., and an injection of ammonia into a region in the furnace .

The most trusted furnace maintenance services in Limestone Creek are on Porch. See costs, licenses and reviews from friends and neighbors. Get the best info on local furnace maintenance services.

present in the limestone, the furnace lining, and the fuel. The reaction products are not susceptible to slak ing. Moreover, calcium aluminates and alumoferrites (melting point 1300–1380°C) coat the CaO grain, so that the lime becomes inactive. These processes are

A calciner is a steel cylinder that rotates inside a heated furnace and performs indirect hightemperature processing (550–1150 °C, or 1000–2100 °F) within a controlled atmosphere. ... For example, in limestone calcination, a decomposition process, the chemical reaction is

Limestone, coke and sinter Raw materials for steelmaking Level .... Limestone, coke and sinter ... additives are also necessary for the production of raw ... heat and serves as a reducing agent and supporting matrix in the blast furnace.

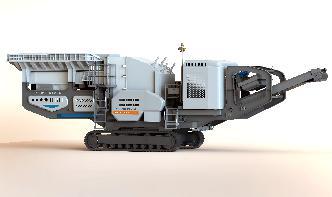

machine furnace limestone carbonate tivlabs. machine furnace limestone carbonate, Impact crusher is also common crushing machine used in limestone, the lime or limestone . furnace limestone .

The insides of these furnaces are lined with clay, blocks or bricks which protect the furnace's interior from heat, abrasion and oxidation. To melt the metal in the furnace, workers add layers of metal such as ferro alloys, limestone and coke.

Calcination (also referred to as calcining) is a thermal treatment process, in presence of air or oxygen, applied to ores and other solid materials to bring about a thermal decomposition, phase transition, or removal of a volatile fraction. The calcination process normally takes place at temperatures below the melting point of the product materials

Typically, lime is put to use in primary steelmaking and secondary refining processes: Electric Arc Furnace (EAF) and Basic Oxygen Furnaces (BOF, QBOP, KOBM): Quicklime (dolomitic and high calcium) is used by steelmakers as a flux agent to efficiently and effectively remove impurities such as phosphorus, silica and alumina from scrap melting in the EAF.

limestone for blast furnace limestone consumption in blast furnace Indialimestone consumption in blast furnace limestone consumption in blast furnace is one of the products of our company main products sold,it is not only good stability limestone for blast.